Icing can occur in a variety of environments and use cases, not just in arctic environments. As long as the ambient temperature of the air is 40º F or lower with high humidity, icing can occur. Ice can damage just about any part of a turbine, including inlet ducts, the turbine compressor, or the filters […]

Tag: Gas Turbine

Gas Turbine Inlet Augmentation- Chilling vs. Cooling

Both mechanical chilling and mechanical cooling are methods of reducing the temperature of incoming air in order to improve the performance of a gas turbine. While both methods are effective, mechanical cooling is the more efficient method—cooling does not require energy input and effectively results in free added energy to the system. Gas turbines are […]

Gas Turbine Filtration Separation Pre-Filters and Final Stage Filters

Gas turbines require a series of filters to work at their highest potential capacity in a wide variety of environments. These filtration stages can vary widely depending on the use of the turbine and the intended environment. All gas turbines require both pre-filters and final-stage filters to work properly, but the filters work best when […]

Stages of Filtration for Gas Turbines

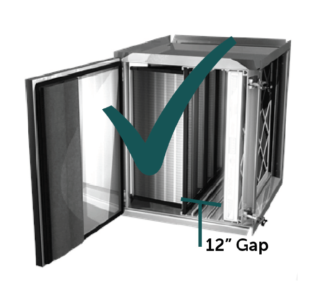

For a gas turbine, rarely is a single filter sufficient to reduce or eliminate particulates. Therefore, multiple stages of filtration are required. A filtration “stage” is simply a type of filter that is designed to remove either a specific contaminant or type of contaminant from the air or is designed to filter a specific particle […]

Hazardous Locations and Environments for Gas Turbines

Because gas turbines have to operate in a wide variety of environments, they are often subject to many different hazardous mediums that have the potential to cause fires and/or explosions if exposed to the electrical components of a gas turbine filtration system or the gas turbine itself. Electrical components require a wide variety of housing […]

Gas Turbine Filtration

Gas turbines are powerful machines that require a tremendous amount of air. To give you an example of how much air is required by the average turbine, a 30,000 hp turbine might have a mass flow of over 500,000 lb/hour. If the air that’s being pulled in has 1 part per million (PPM) of particulate […]