Gas turbines require a series of filters to work at their highest potential capacity in a wide variety of environments. These filtration stages can vary widely depending on the use of the turbine and the intended environment.

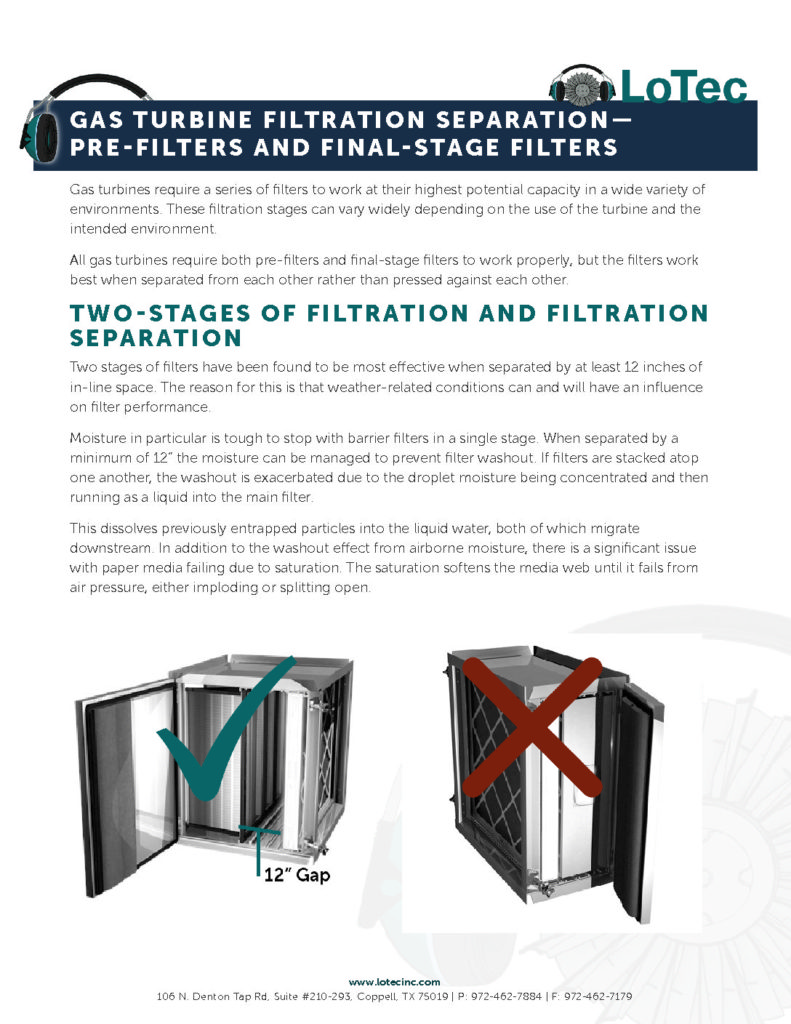

All gas turbines require both pre-filters and final-stage filters to work properly, but the filters work best when separated from each other rather than pressed against each other.

TWO-STAGES OF FILTRATION AND FILTRATION SEPARATION

Two stages of filters have been found to be most effective when separated by at least 12 inches of in-line space. The reason for this is that weather-related conditions can and will have an influence on filter performance.

Moisture in particular is tough to stop with barrier filters in a single stage. When separated by a minimum of 12” the moisture can be managed to prevent filter washout. If filters are stacked atop one another, the washout is exacerbated due to the droplet moisture being concentrated and then running as a liquid into the main filter.

This dissolves previously entrapped particles into the liquid water, both of which migrate downstream. In addition to the washout effect from airborne moisture, there is a significant issue with paper media failing due to saturation. The saturation softens the media web until it fails from air pressure, either imploding or splitting open.