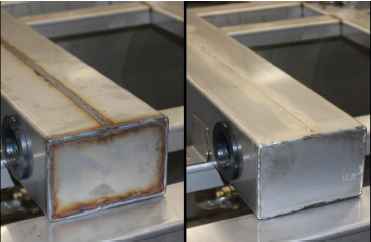

Stainless steel that is more than 11% chromium will create a passive (inert) layer on its surface that self-repairs oxidation. This layer is responsible for stainless steel’s resistance to corrosion. Pickling and passivation is the process of cleaning and resurfacing stainless steel to restore the integrity of the material and this chromium layer after it has been damaged or altered, usually by some change to the material required for industrial applications. The damage is usually structural, such as one would find from welding or bending stainless steel with a brake.

Contaminants can be introduced by the production process, as lapping and other forms of processing can accidentally introduce iron particles, carbon steel particles, and other types of impurities that can then render stainless steel vulnerable to corrosion and rust by reducing chromium levels. With both pickling and passivation, not only is the integrity of the stainless steel restored, but the stainless steel also becomes even more resistant to corrosion and rust.

Pickling, Electropolishing, and Passivation

The difference between pickling, electropolishing, and passivation is one of degrees and intensity. Pickling is considered “intense” and treats the metal on a sublevel basis, changing the metal more than passivation. Electropolishing can be considered an even more intense version of pickling. Passivation doesn’t change the properties of the metal and doesn’t penetrate below the surface. Pickling removes a chromium-depleted layer from the surface through chemical means, such as the use of nitric and hydrofluoric acids. These acids can also be combined with inert carriers to

create a pickling paste.

Electropolishing can be used in place of pickling. Electropolishing creates an even more corrosion resistant surface and a brighter sheen, and also renders the stainless steel smoother on a microscopic level. Passivation is only used to treat the surface of stainless steel and is also accomplished using acid solutions or pastes. Common solutions include nitric acid or citric acid. The acids accelerate the natural process of chromium layers forming a passive, corrosion-resistant layer. However, passivation methods do not penetrate below the surface, nor do they smooth the surface. Pickling, electropolishing, and passivation are the final step in the production process.