There are a number of ways by which you can torque structural bolts. Below are examples of the most common methods used in the field.

Turn of Nut

Turn of Nut is a method by which structural bolts can be tightened without the use of a torque wrench. The reason this is such a popular method is simple—the guide itself is simple and can be understood by anyone, and further, the method avoids the use of tension measuring devices. This simple method takes into account the slope of what is being bolted and the length of the bolt.

Note that Turn of Nut requires first that the bolt has been snug tightened, which means that the bolt cannot be removed except with the use of a wrench.

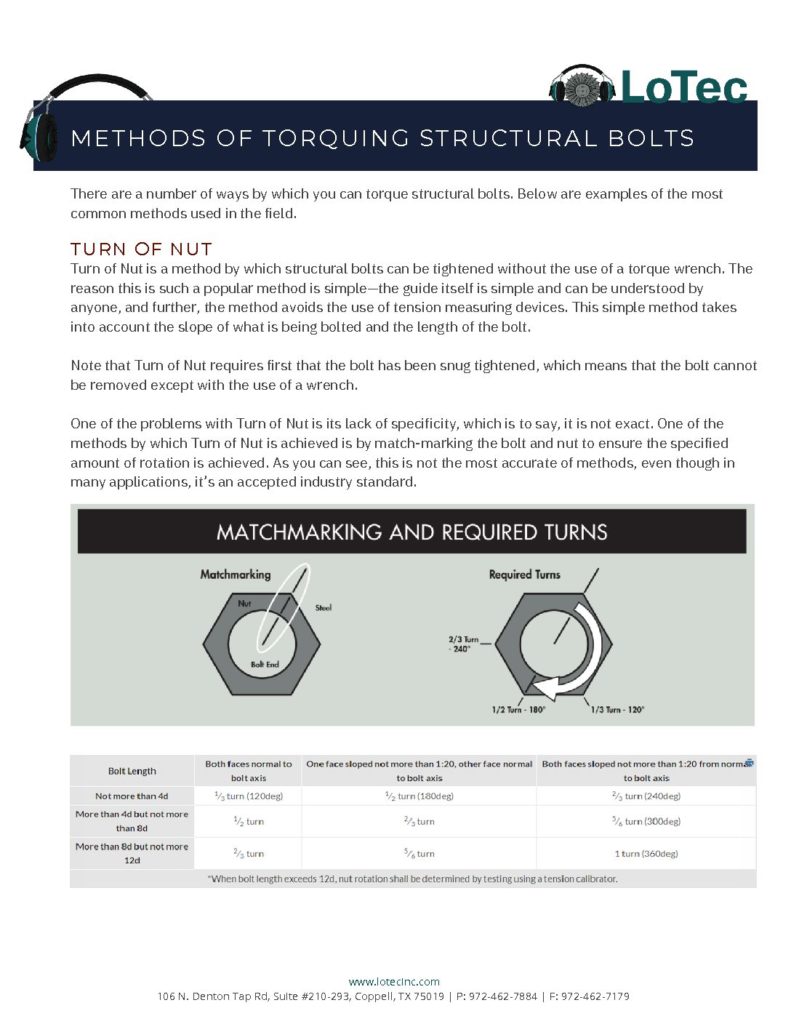

One of the problems with Turn of Nut is its lack of specificity, which is to say, it is not exact. One of the methods by which Turn of Nut is achieved is by match-marking the bolt and nut to ensure the specified amount of rotation is achieved. As you can see, this is not the most accurate of methods, even though in many applications, it’s an accepted industry standard.

Tension Control Bolt Systems

Turn of Nut, while simple, has widely been replaced by Tension Control (TC) Bolt Systems. These systems are approved by the AISC as an acceptable installation method.

The major advantage of these systems amounts to the same advantage that once was seen with Turn of Nut—simplicity. Tension control bolts are pre-assembled fasteners with a rounded head and a splined end that shears off when the nut achieves proper torque. This is a great advantage to using TC bolts as they provide a quick installation procedure that maintains accuracy. TC bolts are also faster to install for this reason. It is still important to remember that, though TC bolts help

confirm that you have achieved proper torque, you still need to ensure your bolts are properly tensioned.

Direct Tension Indicators

Direct Tension Indicators (DTI) are washers used on a hex assembly and are designed to ensure proper tension on bolts. Traditional DTIs have bumps around the washer that flatten once proper tension is achieved. This allows you to have a visual confirmation that tension is achieved.

Both tension TC Bolts and DTI washers can help save time in the field by easily confirming tension or torque is achieved. Whichever method is preferred, remember that bolts are tightened in order to achieve tension—torque is only a way of reaching that proper tension.