While there are many types of filters that can be used in a gas turbine, most can be divided into two categories—barrier filters and pulse filters.

BARRIER FILTERS

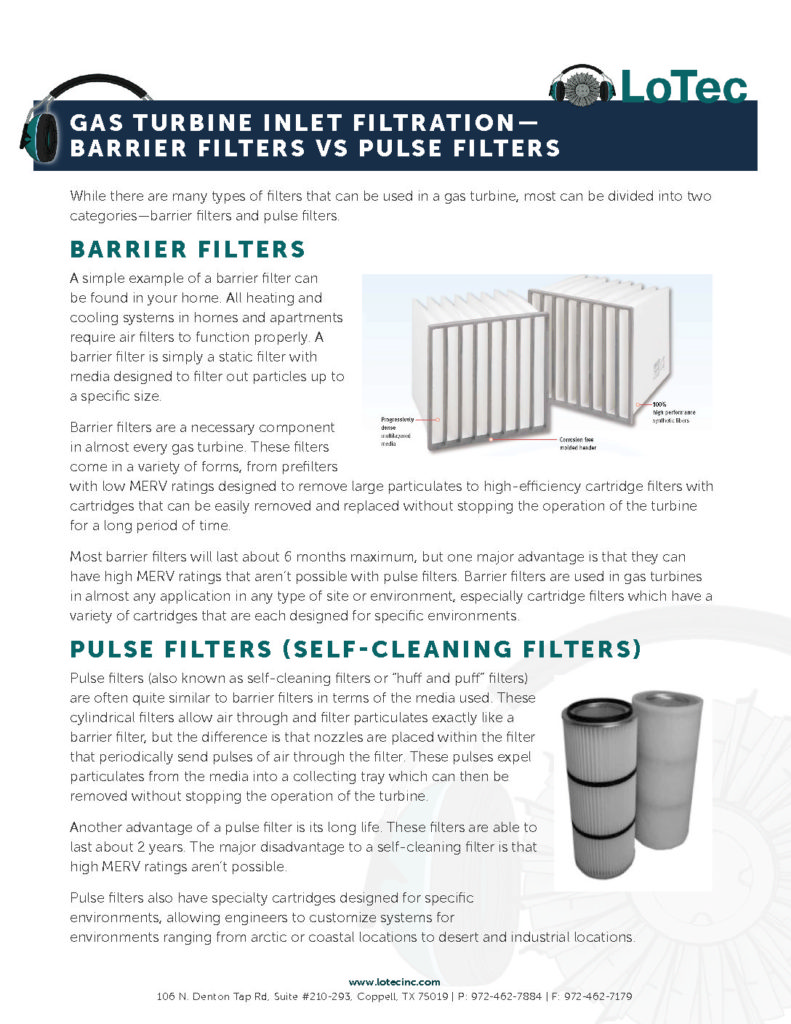

A simple example of a barrier filter can be found in your home. All heating and cooling systems in homes and apartments require air filters to function properly. A barrier filter is simply a static filter with media designed to filter out particles up to a specific size.

Barrier filters are a necessary component in almost every gas turbine. These filters come in a variety of forms, from prefilters with low MERV ratings designed to remove large particulates to high-efficiency cartridge filters with cartridges that can be easily removed and replaced without stopping the operation of the turbine for a long period of time.

Most barrier filters will last about 6 months maximum, but one major advantage is that they can have high MERV ratings that aren’t possible with pulse filters. Barrier filters are used in gas turbines in almost any application in any type of site or environment, especially cartridge filters which have a variety of cartridges that are each designed for specific environments.

PULSE FILTERS (SELF-CLEANING FILTERS)

Pulse filters (also known as self-cleaning filters or “huff and puff” filters) are often quite similar to barrier filters in terms of the media used. These cylindrical filters allow air through and filter particulates exactly like a barrier filter, but the difference is that nozzles are placed within the filter that periodically send pulses of air through the filter. These pulses expel particulates from the media into a collecting tray which can then be removed without stopping the operation of the turbine.

Another advantage of a pulse filter is its long life. These filters are able to last about 2 years. The major disadvantage to a self-cleaning filter is that high MERV ratings aren’t possible.

Pulse filters also have specialty cartridges designed for specific environments, allowing engineers to customize systems for environments ranging from arctic or coastal locations to desert and industrial locations.